Mud flap hangers might seem like minor components, but they play a big role in keeping your truck safe, compliant, and simple to service. The shape of the hanger determines whether your flaps remain secure, avoid the tires on bumpy ground, and satisfy local inspection rules. Picking the incorrect type can cause cracked flaps, shaking, or even expensive downtime. This article outlines the actual difference between straight and angled mud flap hangers and assists you in deciding which one fits your truck or fleet best.

When the Wrong Hanger Causes Problems

- Flaps begin to lift or rip under high-speed wind.

- Tires or pavement contact occurs during air-ride dumps or when the suspension shifts.

- Inadequate coverage results in failed inspections or fines.

- Extra shop time is required for bent hangers and stretched fasteners.

These issues appear straightforward, but they can accumulate into downtime, lost miles, and needless replacement costs.

Straight vs. Angled Mud Flap Hangers

Straight hangers extend horizontally from the mounting point. They are simple to install, easy to align, and perfect for standard trailers and tractors that lack complex rear equipment.

Angled hangers reach backward at about 30 to 45 degrees. This angle shifts the mud flap’s trailing edge away from the tires and rear components, which helps minimize spray and enhance clearance around catwalks, reefer hoses, or tanks.

| Feature | Straight Hanger | Angled Hanger |

| Shape | Flat, no angle | 30–45° backward offset |

| Best for | Standard dry-van and line-haul trucks | Reefers, tankers, dump trucks |

| Key benefit | Easy alignment and replacement | Extra clearance and better airflow |

| Add-ons | Anti-sail bar, stiffener | Reflector plates, stiffener bar |

Both types can perform well when paired with the right vehicle and environment. The selection relies on what kind of roads, weather, and trailer setups you manage.

Choosing by Vehicle Type and Operation

Line-haul and Dry-Van Trucks

Straight hangers are straightforward and tough for long-haul routes. If your trucks encounter strong crosswinds, include an anti-sail bar for stability.

Reefer and Tankers

Angled hangers offer more clearance behind the tail gear and lower the risk of hoses or steps striking the flaps. Combining them with reflector plates boosts night visibility.

Dump Trucks and Off-Road Vehicles

Opt for heavy-duty angled hangers with thicker walls. They endure stone strikes and frame-twisting better than standard hangers.

City Delivery Fleets

Straight hangers are compact and simple to align after minor impacts. They suit situations where trucks back into docks or tight spaces often.

Fitment and Sizing

Mud flaps typically range from 24 to 36 inches wide. Match the hanger width to your flap width and leave enough space above the road surface to avoid dragging.

Always check suspension movement during installation. Ensure the flap never contacts the tire or the ground when the air suspension drops.

When mounting, use stainless or coated steel fasteners with thread lockers and washers. Recheck the torque after a few runs, especially in the first week.

Material and Finish

Stainless steel hangers resist salt, detergent, and rust in harsh winter or coastal conditions. Black-coated or galvanized steel hangers are cost-effective but require occasional maintenance.

Thickness also matters. A thicker hanger is not always stronger; design and hole spacing affect rigidity just as much.

Installation Tips

Position the straight hangers square with the axle centerline. For angled types, confirm the setback distance before tightening. Keep holes clean and smooth after drilling, and tighten each bolt evenly.

If your flaps still flutter at high speeds, add an anti-sail bar or stiffener. They help keep the flaps hanging straight and prolong service life.

Compliance and Safety

Inspectors usually check three things: coverage width, height from the ground, and flap condition. The flap should cover the full tire width and hang close enough to the ground to block spray, but not so low that it touches the pavement when loaded.

A quick pre-trip inspection of height, width, cracks, and fasteners prevents most problems on the road.

Total Cost of Ownership

A cheap hanger that rusts or bends every year costs more over time than a premium stainless model that lasts for several seasons.

Add up the time lost to shop visits, replacement parts, and driver downtime. The higher-quality hanger often pays for itself within two or three years.

Real-World Scenarios

Example A: Long-Haul Tractors with Super-Single Tires

The wider tire surface throws more spray. Angled hangers move the flap slightly backward, enhancing protection and preventing slapping against the tread.

Example B: City Tractors with Frequent Backing

Straight hangers make sense for these vehicles. They are easier to realign and replace if the truck reverses into a dock or curb.

Product Spotlight

Here are four reliable options for different setups:

- Straight Mud Flap Hanger Bracket Set | XKJ-MFH-03-1/2

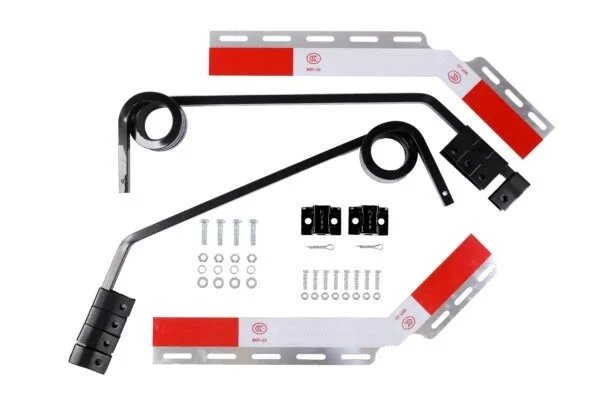

A classic straight design for standard overhangs. Easy to align, quick to install, and proven for long-haul fleets. - Pair of Angled Bar Truck Hangers with Reflector Plates | XKJ-MFH-Q3C

Stainless-steel angled bars with built-in reflector plates that enhance rear visibility. Ideal for tankers or reefer trailers. - Black Straight Bar Mud Flap Hanger Bracket Kit | XKJ-MFH-SBK

A budget-friendly straight hanger set made with coated steel, designed for city fleets that value easy maintenance. - Aluminum Mud Flap Hanger Reflector Plate | XKJ-MFS-S24AL

A lightweight reflector plate accessory that improves night safety and pairs with either straight or angled hangers.

Quick Buying Checklist

- Identify the trailer type and tail equipment.

- Simulate full suspension movement to confirm clearance.

- Select finish and material based on climate conditions.

- Add reflector plates or anti-sail bars if you drive in rainy or snowy areas.

- Standardize flap widths (24, 30, or 36 inches) across your fleet to make replacement easier.

For more professional options and fleet supply kits, visit truck mud flap hanger accessories for detailed specifications and trade-friendly bundles.

Maintenance and Replacement

Inspect hangers weekly for bending, corrosion, or loose bolts. Replace if you see elongated holes or flaps that no longer hang straight.

During seasonal service, clean off salt and road grime. Touch up coating if needed and re-torque all mounting hardware.

Regular checks can extend the life of your Black angled spring-loaded mud flap hanger set and ensure safety performance over years of operation.

FAQ

Do angled hangers always reduce spray?

Not automatically. Proper coverage and flap alignment matter more. Angled hangers help when the tail has complex equipment or airflow issues.

Can straight and angled hangers be mixed in the same fleet?

Yes. Choose based on the vehicle’s structure. Many fleets use straight-on tractors and angled on trailers for flexibility.

When should reflector plates be added?

For night routes, heavy rain, or foggy conditions, reflector plates such as aluminum mud flap hanger reflector plate for a semi truck increase visibility and help prevent rear-end accidents.

Conclusion

Both straight and angled mud flap hangers serve a vital purpose. Straight hangers deliver simplicity and strength for most line-haul operations, while angled hangers provide clearance and control for trucks with special rear layouts.

When choosing, consider your route, vehicle type, and maintenance routine. Investing in quality hangers and proper installation will not only extend flap life but also reduce safety risks and downtime.